Rebuilding for Performance: How IGE Fans Extends the Life of Industrial Equipment

At IGE Fans, repair and rebuild are synonymous — both represent our commitment to helping customers get more life and better performance from their existing equipment. Whether it’s a small blower or a 12,000lb high-temperature axial fan for a homogenizing furnace, our engineers don’t just restore—we improve.

Every repair or rebuild that comes through our doors is an opportunity to make a design better. Using decades of fan design expertise, advanced reverse engineering, and in-house manufacturing, we often upgrade materials, improve airflow efficiency, and increase durability so rebuilt fans perform like new — or better.

Explore our full Repair & Rebuild Services

Design Improvements That Go Beyond Restoration

When a fan shows up at IGE for evaluation, we don’t just fix what’s broken. We assess every component for potential performance gains — from bearing & drive selection to alloy corrosion resistance and airflow optimization.

Our 53-point inspection process ensures that each rebuild meets or exceeds original specifications. And if a rebuild isn’t cost-effective, we provide high-performance, direct-fit replacements that outperform the originals.

Every rebuild comes backed by:

- 2-year warranty — unheard of for repairs & rebuilds

- Design enhancements based on 100,000+ global installs

- Improved efficiency and material upgrade

- Standard 6-week lead time (rush options available)

Case Study: From Mild Steel to Stainless — Brick Furnace Fan Rebuild

Case Study: From Mild Steel to Stainless — Brick Furnace Fan Rebuild

A great example of IGE’s rebuild expertise comes from a project earlier this year. A customer sent in a set of badly worn German brick furnace fans — with no OEM documentation and severe material degradation.

IGE engineers reverse-engineered the design, salvaged usable components, and completely rebuilt the units using stainless steel for the hot-face and wheel assemblies. The result?

- Extended service life

- Dramatically improved corrosion resistance

- Cost savings compared to full replacement

The upgraded stainless-steel design ensures these fans will withstand years of continuous, high-temperature service with minimal maintenance — proof that a well-engineered rebuild can outperform the original.

Case Study: Rebuilding a 66” Axial Fan — Big Power, Renewed

Case Study: Rebuilding a 66” Axial Fan — Big Power, Renewed

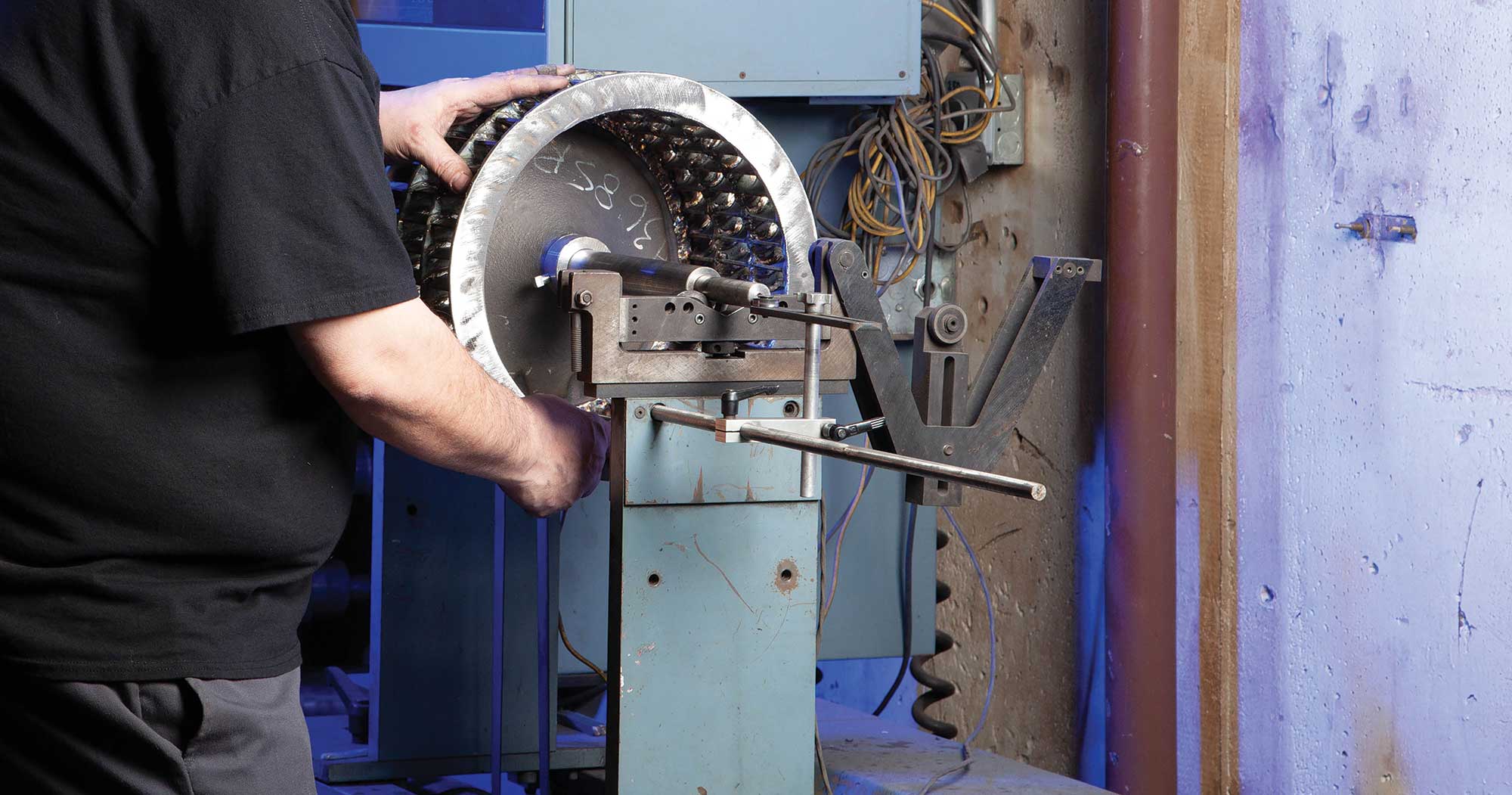

Not all rebuilds are small projects. When a 66-inch aluminum homogenizer fan arrived at IGE, it showed extensive wear from years of operation. Our team performed a full teardown and inspection using NDT methods, including dye penetrant testing. The existing 6-blade Robinson Fans fan wheel showed extensive cracking and was replaced by IGE’s 10-blade design, which can deliver superior performance and operates at a fundamentally lower stress level than the existing design.

The unit was reassembled with improved materials and both the impeller and complete fan assembly were re-balanced to ensure smooth operation.

This large-scale rebuild restored the fan to like-new operation — ready for a long service life in a demanding industrial environment.

Repair or Replace — We Help You Decide

Not every unit is worth rebuilding. That’s why IGE offers free inspection and repair quoting to determine the most cost-effective solution for your operation.

If rebuilding isn’t practical, we can supply high-performance, direct-fit replacements engineered to exceed OEM standards in durability and efficiency.

Whether it’s an IGE unit or another manufacturer’s design, our goal is always the same — to keep your operation running reliably, efficiently, and safely.

Don’t let worn-out fans slow you down.

Partner with IGE Fans to restore performance, reduce costs, and extend equipment life — with the industry’s most trusted rebuild program.

Leave a Reply